Tech:Electrical/Starter Motor/Planetary Type

Planetary Type

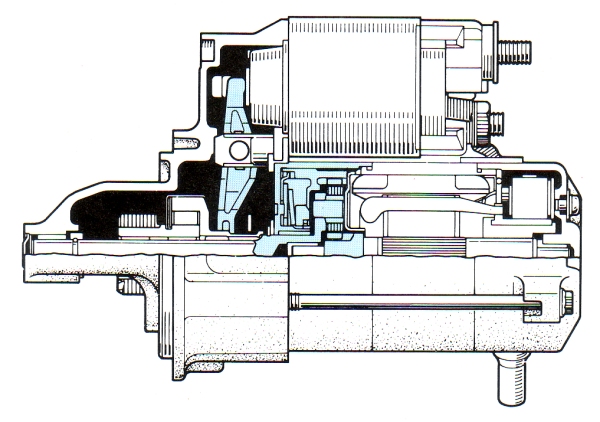

Construction

The planetary type starter uses planetary gear to reduce the rotational speed of the armature, As with the reduction type, And the pinion gear meshes with the reduction gear via a drive lever, As with the conventional type.

Operation

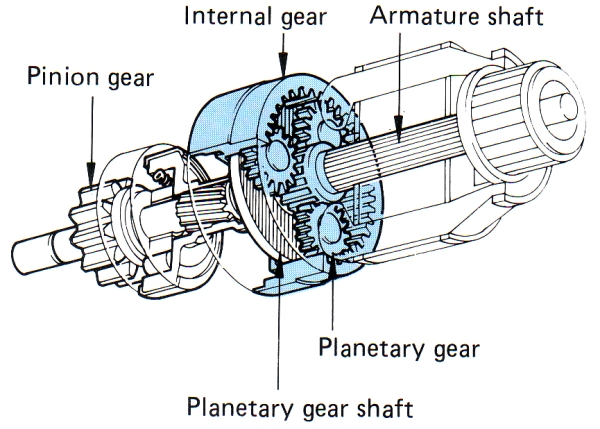

- 1. Speed Reduction Mechanism

Reduction of the armature shaft's speed is accomplished by three planetary gears and 1 internal gear. When the armature shaft turns, The planetary gear turns in the opposite direction, Which attempts to cause the internal gear to turn. However since the internal gear is fixed, The planetary gears themselves are forced to rotate inside the internal gear. Since planetary gears are mounted on the planetary gear shaft, The rotation of the planetary gears cause the planetary gear shaft to turn also. The gear ration of the armature shaft gear to the planetary gears and internal gear is 11:15:43, Which results in a reduction ratio of approximately 5, Reducting the rotational speed of the pinion gear to approximately 1/5 of its original speed.

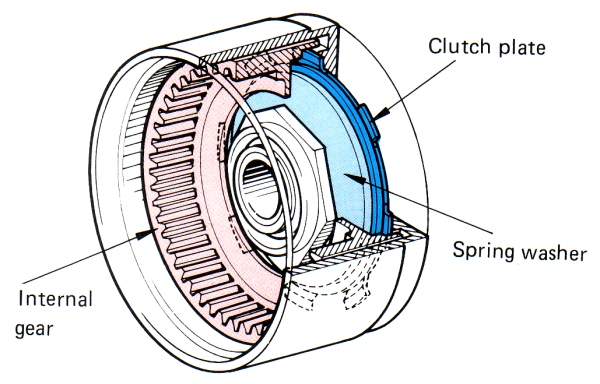

- 2. Damping Device

The internal gear is normally fixed, But if too much torque is applied to the starter, The internal gear is caused to rotate, Allowing the excess torque to escape and preventing damage to the armature and other parts. The internal gear is engaged with a clutch plate and the clutch plate is pushed by a spring washer. If excess torque is brought to bear on the internal gear, The clutch plate overcomes the pushing force of the spring washer and turns, Causing the internal gear to rotate, In this way, The excess torque is absorbed.

Back to Starter Motor

Back to Main Page