-

Posts

2154 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by oh what a nissan feeling!

-

-

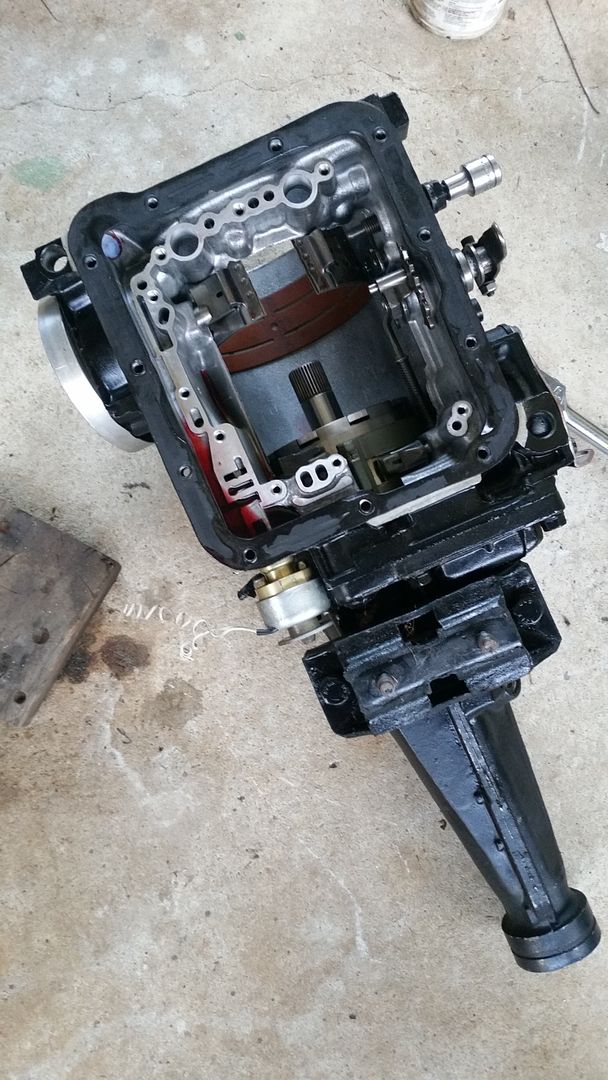

I pulled the new gearbox apart, i bought it 2nd hand brand new, so checked out if it has the good bits its supposed to. things went well, definately an als race glides box due to the 5 pin planet.

tubs fitted

My new c4 adaptor plate is thicker than the old one, i was going to mill 5mm off it. Then i discovered the spigot on the stall was only just long enough and machined too small as well. so i decided i may as well space the stall 5mm instead. still need to get the spigot machined as my lathe is too small to grip it properly.

i going to run twin pickups from the tank, so this expensive this was required.

The work i was doing to floor is finished, new super strong front leaf mount tied from the rail to the sill of the car, and a few other clearance issues all sorted.

-

That one is a bad design for air distribution to the cylinders. An easy way as a starting point is on a good plenum when you look through the throttle body you should be able to see all of your runner bellmouths. So on that plenum cyl 1 is going to starve.

-

What is it you want to know, how to find him to buy one? The design is not great..

-

Ive never seen that before, looks pretty cool i recon

-

S13 block with s14 head will need oil restrictors in the block changed. Don't usd the silvia tailshaft as the unis are not replaceable, use an older datsun one.

Show us some pics!

-

Your diff has not moved because of lowering. Your leaf bushes could be stuffed so check them out. If its not that, old card were built with a low accuracy so it would not be unusual to have that amount of variation in a chassis.

-

That one depends entirely on your engineers opinion, some of them allow it in the boot no box at all. Some wont allow it in the car. My brothers engineer made him seal the boot off from the cabin.

Have you seen those filler fitting you can bolt to the top of your fuel cell? A hose off one of them might work if you don't love the factory tank.

-

Just read it too, wow I'm impressed with their knowledge! I have never met one with even half a clue.

-

I didnt realise tas was under ncop, interesting. Yep prob need to change the wheels for track correction, some engineers want the car to be full rwc before engineering, some don't so it may not come up. Under ncop the suspension is fine, qld rejected that section of ncop :( fuel filler has to be outside the car. Engineering is usually a pretty easy process.

-

It sounds like factory sealer, it does catch on fire with enough heat but not badly. I usually blow it out and keep welding, it doesnt really like to burn and goes out easily.

-

Not going again still, getting close though, painting and bolting things in. Many pics i will put up soon.

2.2 nitto crank arrived today in the mail. Excellent.

-

It is pretty unlikely i think, and usually wouldn't be an issue at all.

but it may be a possibility if i completely cleaned and degreased the gearbox when i had it apart, so the gearbox is completely dry of oil. i honestly can't remember for sure if that was the case, even then you would probably have to run for more than just a few quick starts.

-

It does sound like the bearing might be dragging on the clutch like you said, can you remove the boot in the side of the box and have a look, maybe one of those supercheap mirrors needed. sounds like you may have to shorten the rod under the dash, or the one on the gearbox to get your clutch in a better spot. Unless the box is on a really bad angle it shouldnt be the oil, if you are unsure an extra half a litre wont do any harm at all.

The input bearings on the box are brand new japanese bearings, as well as the output bearings, so that would be very unlikely.

-

Sounds like thrust bearing, clutch should have come with a new one?

-

if you do that rather than run spacers just get some wheels sorted that have epic dish and minimum backspacing. win win.

personally i would be shortening it more than factory length anyway to get some better dish on the rear wheels, but i guess that depends what look you are going for. on my ke30 the new diff is 40mm shorter per side.

-

what he is saying is correct, axels stay small just after the spline so can't be resplined until you cut enough off them. the usual process is to put the short axel in the long side and then shorten the long axel a fair bit. because your diff is very close to the length required though this wont work either.

my suggestion would be to use the long axel in the short side and have it splined at the length you require. then source the long axel from an r31 or pintara or something else suitable and have it cut and splined and machined to take your bearing ect to suit your diff.

i only suggest r31 or pintara because of stud pattern.

-

on my ke30 it would have gained 2 to 3 inches i think, i still have 2" reset springs in there as well and a 2" lowering block built into my diff. if you just did the rear you would get 1/2 of what you cut out. not sure on the ke25 if the possibilities are the same.

-

Very nice build mate. I have done what you say to my ke30, i cut the rear mount down so the tube sits directly on the chassis. I have also done the front mount though, i initially changed the front mount to add strength to the mount and to tie it better into both the sill and the chassis rail, while doing that i also lifted it around 3 inches closer to the floor to lower the car further.

-

It turns out the one i had found works opposite to what i need, so full is 110 and 0 is empty. so no luck yet, i can use one from another vehicle but it needs to be e85 compatible, so not real common. It may come down to using an autometer guage.

-

mines a 76 model with the early dash. cheers for that cuzzo thats very handy, it matches pretty good for a boat sender i have found so very happy. thanks again.

-

I need to run a universal sender in my tank because the stock one doesnt love e85.

Does anyone know, or could please measure the resistance of the stock fuel sender on full and on empty. if i could get this info i could match it to an aftermarket sender.

So if anyone has a ke30 sender lying around they could put a multimeter on ohms to it, or a manual that tells the story. I have a gregorys manual and its not in there. cheers matt

-

Have a look at my ke25 thread, the same will be required for a ke30 if the height of the rad support is the same. can't link it I'm on a crap phone

-

Awesome, that looks epic!

-

mine is jb1762, it is externally identical to the one pictured. the difference is likely internal, usually the later model would have a bigger bore.

Matts Ke30......sr20det

in Rollaclub Rides

Posted

Making the new mounts for the diff, i finished these today.

I really wanted to upgrade the front bolt for the leaf spring, since it has the caltracs raging at it as well. problem was there was not much room left for the nolathane bush. I made a brass bush and machined a new crush tube to fit snug inside of it, will grease it up and see how that goes. I'm still going to run rubber either side of the spring to keep a lil bit of tension on the caltracs so they don't rattle. Making new caltracs triangles as well to run a bigger bolt than before.

new rear main seal now installed.