-

Posts

2154 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by oh what a nissan feeling!

-

-

It sounds like your engine is positioned slightly different to mine. I don't have the brake light switch connected, but the rest is normal. Your best bet would be to use the master and booster off an early ke30 i guess, it will give the clearance you need. As an upgrade that will bolt to that booster a pajero master cylinder is often used.

-

the commodore master i use is identical externally to the standard ke55 one and mounts to the ke55 brake booster. it is internally 15/16. when i had a standard intake on mine it was tight on that side but fitted fine with more than 10mm clearance.

talk to jordan, the kit may be made to work with the ke30 brake master and booster which is a much smaller setup.

-

Is your engine s13 or s14. What mounts are using?

-

they do just bolt in, use a grinder and cut 5mm of the spline on both axles. if you are using flares the extra length in the conversion wont be an issue. for the front ke30 brakes and hubs work, just need to use the right bearings to suit.

-

1

1

-

-

just to clarify your question, are you just going to use ke30 axles and brakes in your diff, or are you looking at the 2nd method?

-

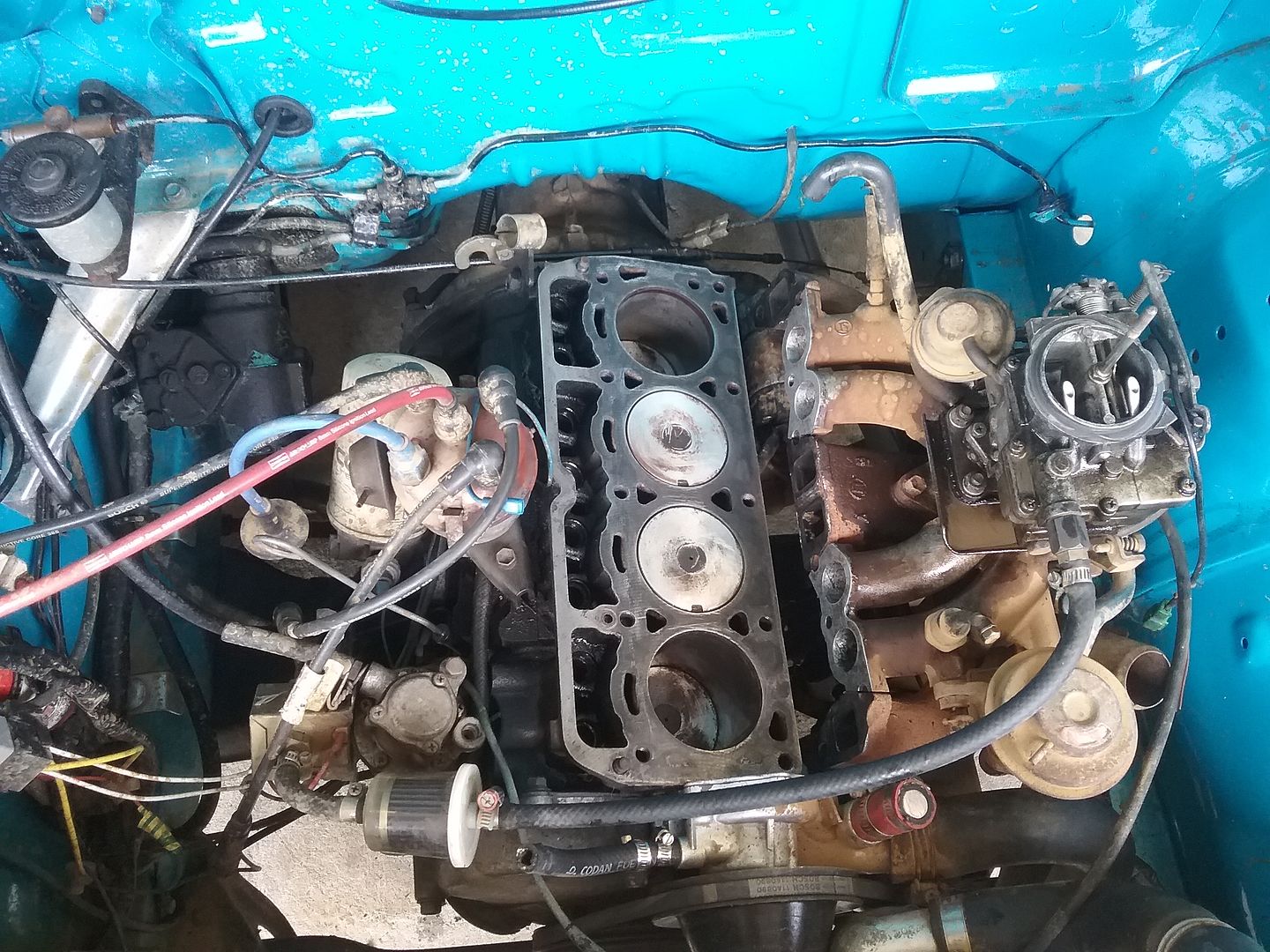

youre right, i blew a headgasket on my skyline and that was a long term affair. trying to explain to the missus that yes its done the same thing as the skyline, but no it will be fixed by lunchtime was quite funny, she didnt understand. gotta love these old things.

-

I drive this lil old beast to work every day, i put 30 litres in it per fortnight to drive 1hr 15 min per day, .so its a good thing really.,

anyways its been running a bit sick this week, and been using a heap of water with no visable leaks, so i thought bhg. it blew a pipe a few months ago too so it got a good cooking.

anyways i go to the shop yesterday, come out and she cranks half a turn then stops suddenly. so i think waterlock. i call up my mate ash to come rescue me with a spark plug socket. he rocks up, tells me it needs a 13b, pulls the plugs, crank her over and number 4 sprays a load of water out. so we quickly chuck the plugs back in and i drive the old beast home.

so an hour later about 1 pm yessterday the head is sitting on my floor and I'm calling around for some head gasket.

So today i put it all back together, went to repco at 9, picked up the vrs, to the old mans for the torque wrench, had it all back together by 1. not how i planned my sunday morning but happy to be driving to work tomorrow.

-

Not yet sorry mate, i have been working on it a heap, but have bitten off a lot of work this time. Was really keen to do powerplay this weekend but yeh missed the goal by a lot. Hopefully another month will see it done. Cheers

-

Which one carlos the ta22 master? I can get it tomorrow i think i have a pbr box in the shed.

-

yep i did mate.

-

1

1

-

-

What greenmac said, the problem with acrylic paint is it is not 100% waterproof so it can take on moisture and then you have that issue. Epoxy is 100% waterproof so even if there was some sand residue on your panels nothing is getting through to start any reaction.

-

i used a ta22 one in my ke30 when it was manual, a pajero nh one is also a very popular for conversions because its very short and is big bore.

-

1

1

-

-

nice mate, mph says there's plenty left in it with some good tyres.

-

nice work mate, what mph?

-

cheers man, repair money is spent now and converter is in the post atm so back on track.

time has been an issue the last 2 weeks, I'm probably halfway through the metalwork now, but behind where i wanted to be.

off to fraser island next week, then a week at home on this i hope, then to yamba for a week. the goal of feb powerplay will feel pretty close by then so i hope that week at home goes well!

-

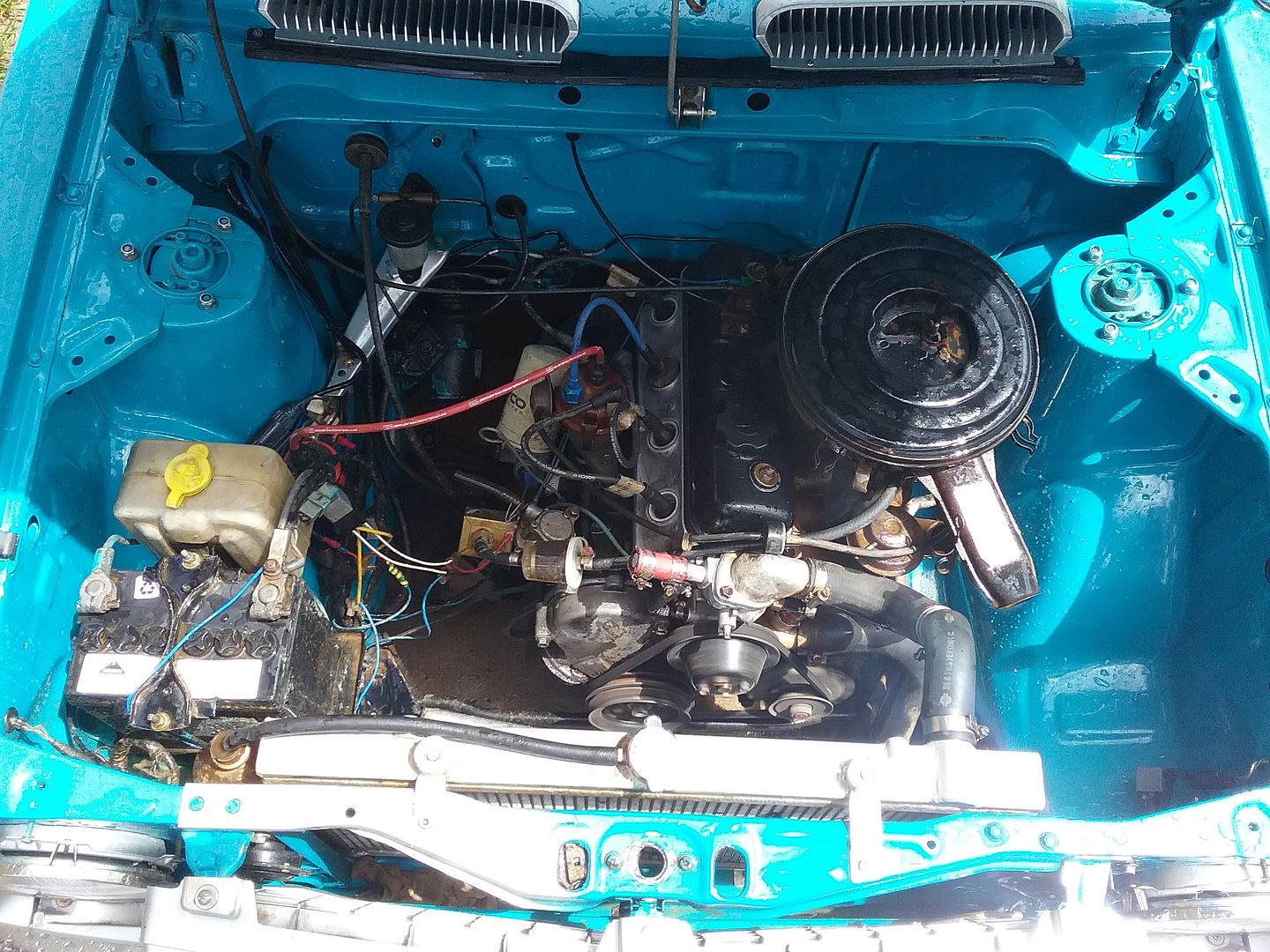

engine bay looks awesome, love the red tubes and gears works really well in there.

-

Yep clowns, how do businesses like that still function.

I'm going to be making a new fuel tank for this now, the old one doesnt fit as well as it used to, it will be good to ditch the surge tank as well with a better tank design.

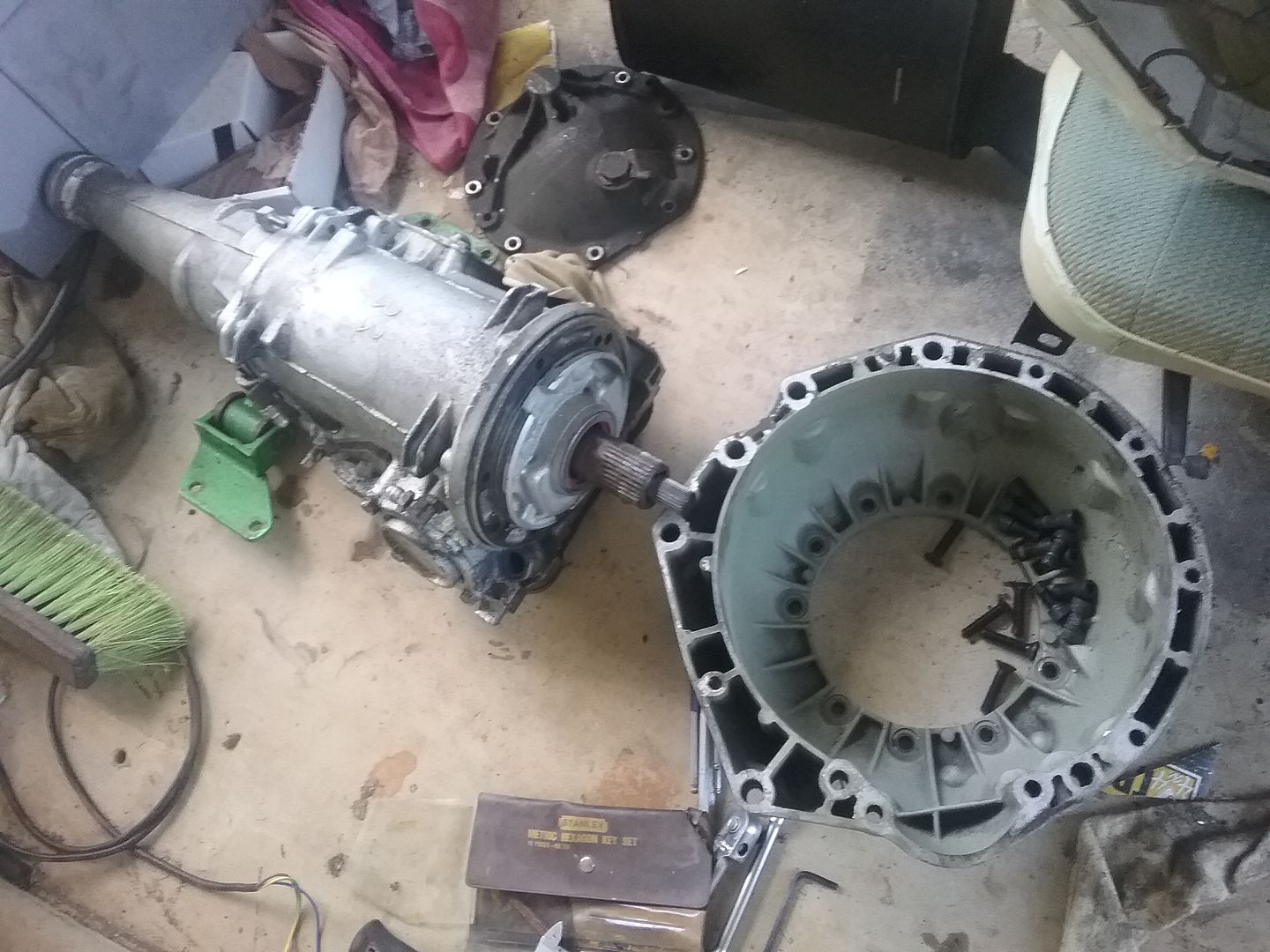

Picked up the diff, center is put together, billet 31 spline with cro-moly studs. overkill yes, but may as well go 31 if I'm building a diff anyways.

I'm going to a steel adaptor plate for the trans, the alloy one is ok but i would feel better with the steel one in there. Problem is the steel one is 5mm thicker so may have to mill it down, or maybe space the converter. will check once the converter is back with me.

out with the old box, and in with the new. transbrake, ect.

alloy for intake runners

-

Mine is the same as in your pics springers , i have a factory ke30 cable and it is in my ke25. I have washers under the rubber block at the firewall, and spacers at the bellhousing as well. It works fine, but I do wonder why the length issue as well.

I bought one of those ke20 cables off ebay, it ended up being exactly the same length except it was such a terrible cable the clutch was almost unuseable.

-

wow that tank looks so good, i was going to do the welding on mine myself, i don't think i will after seeing that! so tidy.

-

ragequit.

My stall converter was built by slingshot. So I ring Slingshot about my stally, the stall speed off boost is around 1500 rpm, its an 8" race converter and was ordered as a 4500 rpm stall. $1600 worth. I ring slingshot twice and discuss the issue with them. I can't get boost at all on the brake, the car does go well on boost though. but no off street drags or skid comps because getting on boost from a stand still is a pita. The owner at slingshot is a great salesman, but quite frankly gave me no confidence as his knowledge of the topic seemed to be very limited, blaming my engine, my gearbox, and then the spec sheet I must have filled out wrong...... So I sent my stally off to TCE to get adjusted.

Fast forward to yesterday I get a call from TCE. The first thing he says is "have you had a massive gearbox failure in the past with this converter?". No its brand new, done less than 5000 ks. He then goes on to tell me that the stator and the turbine have fin damage all over them that has happened in the past. but that's not the whole story. Apparently the stator and the turbine are extremely old items in a brand new converter, showing years of wear all over them, and really poor clearances. He also tells me that there is no way the damage has occurred in this current converter build because there is no evidence of it anywhere else in the converter. Besides my gearbox would have to suffer major failure. He also tells me that the stall speed of 1500 rpm is about right for how the converter is setup. He sent me a heap of pics on my phone. Cost to fix is $1050.

So basically my converter was built from the junkyard.

So I ring slingshot, once again I get the owner a very good salesman, he listens to my rant very very patiently for nearly half an hour. He tells me he's very sorry for my negative experience with his company, but due the to the age of the converter is not interested in helping me with my problem.

I hate cars.

I hate people.

-

love it mate looks nuts sitting out on the road in those pics. let us know how she goes!

-

The front bar looks better now imo, so much better without the rear wing too. Sold my r34 last weekend, I had 5 cars regoed which is just dumb!

-

Hey mate, my leafs have been reset to be lowered a fair bit, plus the 40mm on the diff. I don't have inverted eyes on mine though and they still have a bit of curve in them.

Yeh the u bolts are larger than the stock ones, i would think the factory spring plates could be re-drilled to suit, if not most utes run the same size u bolt that is required. My spring plates are off a mazda b1800 but as you noticed they use the pin type shock, so i run ea falcon shocks. I would look at the hilux ones to use the factory style shock

Tailshaft would require sourcing an r31 tailshaft and getting that end grafted to the corolla tailshaft, should be $200- $300 to get that done.

I will get a weight later, need to pull my stuff off it, would need to be on a pallet so start with 1200x1200x140 around 20kgs for a light pallet, i will get he rest! cheers!

Disk conversion for the t series could be done pretty easy if you start with either r31 brakes, or ea falcon brakes. because of the way the calliper bracket is designed on both of these it makes them really easy to convert to anything, i have done a few random diffs, the worst of the bunch required $100 worth of milling, mostly its just redrilling a few holes.

-

wheels look good mate! why r34 cooler, do they bolt straight up?

Master Cylinder

in KExx Corolla Discussion

Posted

Series 2 paj, nh to nj. So 92 to 95 probably all the way to 2000 as well but i havnt checked.